Top-Rated Houston Welding Inspection Solutions for Industrial Criteria

Top-Rated Houston Welding Inspection Solutions for Industrial Criteria

Blog Article

Exploring the Fundamentals of Welding Examination: An In-depth Evaluation of Procedures, Devices, and the Importance of Top Quality Control in Welding Industries

Welding evaluation serves as a foundation in the maintenance of safety and architectural stability throughout numerous markets. Recognizing the ramifications of these techniques increases essential inquiries about their performance and the future instructions of top quality guarantee in welding.

Importance of Welding Inspection

Welding assessment plays a crucial duty in guaranteeing the stability and safety and security of welded frameworks. It functions as an organized technique to evaluating weld high quality, identifying possible problems, and making certain conformity with well-known criteria and specifications. The importance of welding examination expands past plain adherence to guidelines; it is pivotal in safeguarding human lives and shielding investments in facilities.

Malfunctioning welds can cause devastating failures, leading to significant financial losses, injury, or death. For that reason, rigorous examination procedures are important to discover concerns such as insufficient penetration, porosity, or splits before they intensify right into crucial failings. Furthermore, efficient welding evaluation adds to the overall efficiency and longevity of structures, ensuring that they can stand up to the conditions for which they were designed.

Furthermore, the implementation of welding evaluation cultivates a culture of top quality and responsibility within the welding sector. By prioritizing inspection, organizations demonstrate their commitment to quality, thereby improving their track record and competition in the marketplace. Inevitably, welding inspection is not simply a step-by-step action however a basic element of design honesty and safety and security guarantee, crucial for the successful execution of welding projects throughout different sectors.

Trick Assessment Processes

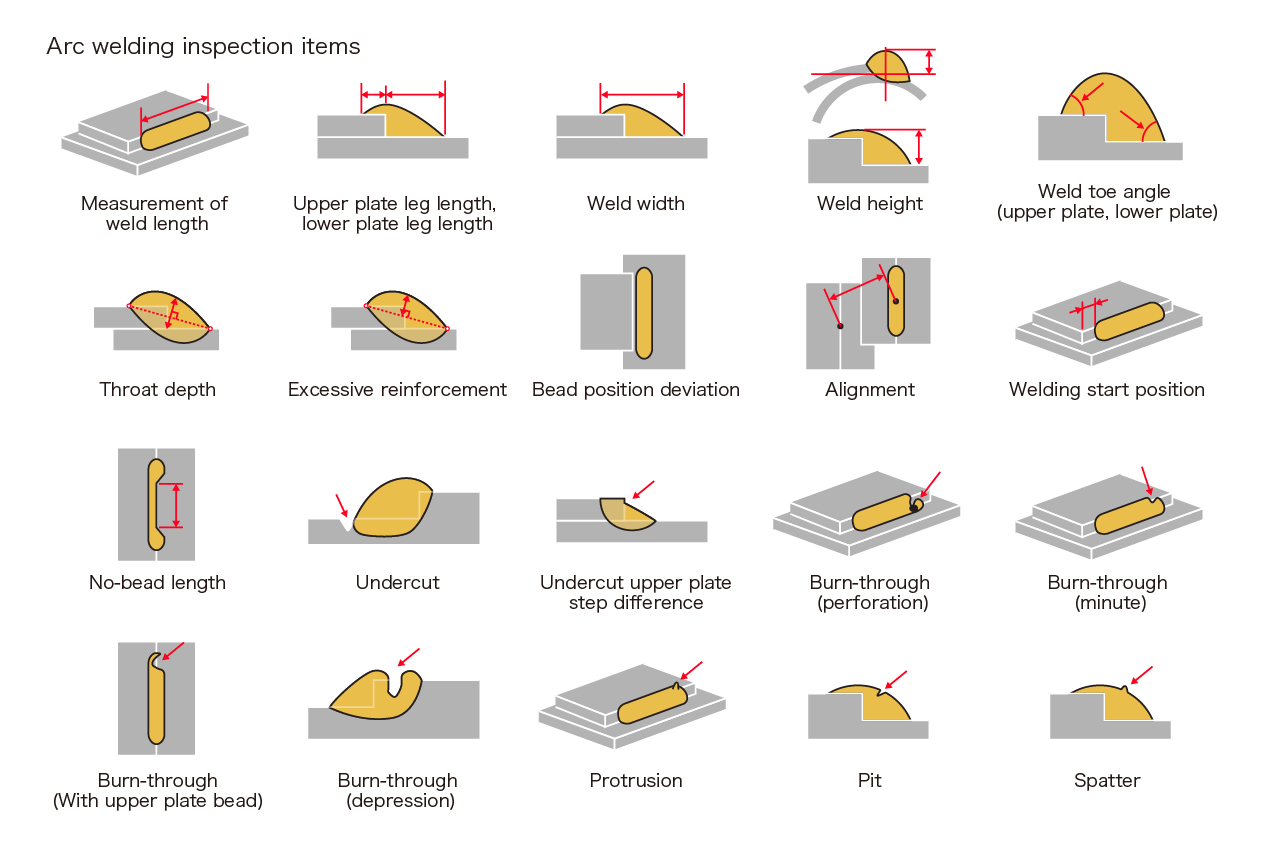

An extensive strategy to welding assessment involves several key processes that are essential for guaranteeing weld quality and architectural stability. The initial critical process is aesthetic assessment, which permits assessors to recognize surface flaws such as splits, porosity, and improper grain look. This method works as an initial assessment to ensure that the weld satisfies specified criteria.

In addition, destructive screening may be performed on example welds to analyze their mechanical residential properties and performance under anxiety. This process entails effect, tensile, and tiredness screening to validate that the weld can stand up to operational problems.

Lastly, documents and reporting are critical parts of the inspection process. Keeping exact records of assessments, observations, and examination results aids ensure compliance with sector requirements and facilitates regular enhancement in welding techniques. Collectively, these crucial processes develop the backbone of reliable welding inspection and quality control.

Devices for Weld Evaluation

Numerous tools are essential for reliable weld analysis, each created to evaluate various aspects of weld high quality and performance. Amongst the most extensively made use of are aesthetic assessment devices, including magnifying glasses and borescopes, which allow inspectors to determine surface area problems such as fractures, porosity, and incorrect fusion.

Additionally, ultrasonic screening (UT) tools is critical for spotting internal imperfections. This device utilizes high-frequency acoustic waves to reveal interruptions within the weld, making sure the honesty of the product. Radiographic screening (RT) devices, which make use of X-rays or gamma rays, in a similar way give insight into the inner structure of welds, enabling the identification of additions or voids.

For exact measurements, calipers and his response assesses play a significant function in figuring out weld measurements and making certain adherence to specified tolerances. Hardness testers evaluate the mechanical residential or commercial special info properties of the weld, ensuring it meets efficiency criteria.

Techniques for Analyzing Quality

How can the top quality of welds be accurately examined? A variety of strategies are utilized to evaluate weld honesty and make sure adherence to specified criteria. Visual evaluation is one of the most essential method, permitting inspectors to recognize surface defects such as fractures, porosity, or undercutting. This non-destructive strategy functions as a first evaluation prior to advanced methods are used.

Ultrasonic screening (UT) is another famous method that makes use of high-frequency audio waves to identify interior defects within the weld. Houston Welding Inspection. This method provides a thorough view of the weld's integrity without compromising its architectural integrity. Furthermore, radiographic testing (RT) employs X-rays or gamma rays to expose internal problems, offering comprehensive webpage insights into weld high quality

Magnetic bit testing (MT) is efficient for identifying surface area and near-surface stoppages in ferromagnetic materials, making use of electromagnetic fields and colored bits to highlight issues. Color penetrant testing (PT) can be utilized to discover surface-breaking flaws by applying a dye that seeps right into cracks and is ultimately disclosed.

Compliance With Industry Specifications

Compliance with market standards is vital for making sure the high quality and safety and security of bonded structures. These standards, established by organizations such as the American Welding Society (AWS) and the American National Specification Institute (ANSI), supply standards that govern the welding procedure, materials, and evaluation procedures. Sticking to these criteria not just makes sure the structural honesty of welds however likewise reduces dangers connected with failures that can bring about disastrous repercussions.

Welding examiners are charged with confirming compliance with these standards throughout the welding process (Houston Welding Inspection). This involves evaluating welding procedures, monitoring welder qualifications, and performing detailed assessments of the end product. Non-compliance can result in substantial monetary repercussions, task delays, and damage to a firm's track record

Moreover, compliance cultivates a culture of quality assurance within the organization. By establishing clear assumptions and benchmarks, companies can preserve consistency in their result and improve general performance. Normal training and updates on criteria are vital to maintain personnel educated and experienced, guaranteeing that all aspects of welding procedures fulfill or surpass regulatory demands. Inevitably, commitment to market requirements functions as a structure for excellence in the welding industry, advertising security and integrity in bonded structures.

Conclusion

In final thought, welding assessment functions as a vital part in keeping the safety and security and honesty of bonded frameworks. With the application of crucial assessment processes and the application of advanced devices and methods, prospective flaws can be determined and resolved successfully. Adherence to sector criteria makes certain conformity and promotes a culture of high quality within the welding industry. Eventually, rigorous assessment methods not only protect human lives yet additionally improve the sturdiness and performance of welded buildings.

Furthermore, the implementation of welding assessment fosters a culture of high quality and accountability within the welding sector. Eventually, welding evaluation is not merely a procedural action however a basic element of engineering integrity and safety and security assurance, vital for the effective execution of welding jobs across different fields.

A detailed approach to welding examination includes several crucial processes that are crucial for making certain weld quality and architectural honesty. These criteria, established by companies such as the American Welding Society (AWS) and the American National Requirement Institute (ANSI), supply standards that govern the welding procedure, materials, and assessment methods.Welding inspectors are entrusted with verifying compliance with these criteria throughout the welding process.

Report this page